SOLAR POWER

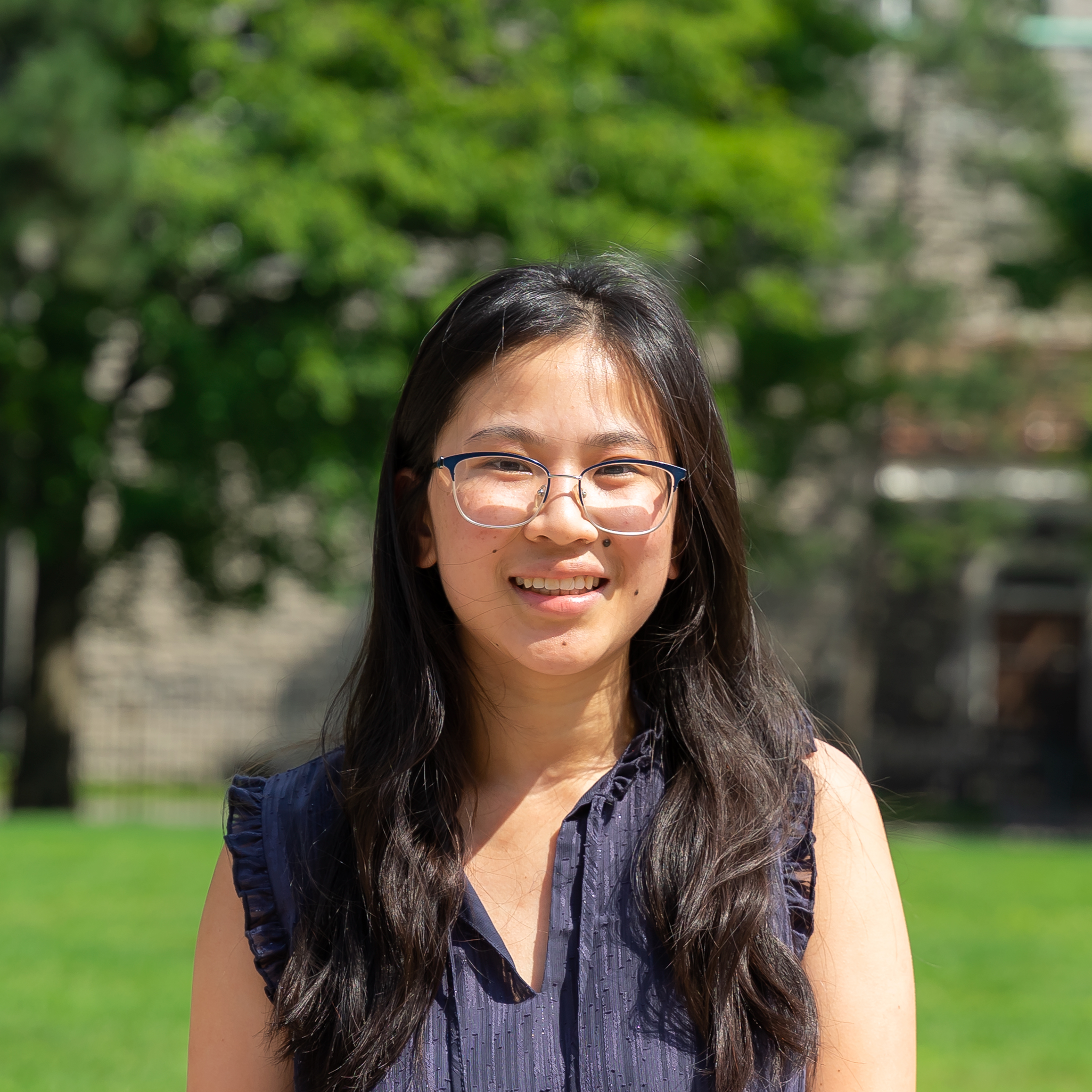

Growing up in Saskatchewan, Erin Tonita often found herself staring up at the stars, wondering about the universe above her. Astronomy, of course, had always excited her as a child and it has remained a passion to this day. In highschool, science and in particular, physics stood out to her and was described as “a challenging draw”.

Today, she finds herself working at SUNLAB, a solar research group at the University of Ottawa where she focuses on photovoltaics, which to her younger self may come as a surprise. However, it comes as a happy mixture, made up of equal parts physics (space) and renewable energy (the environment).

The Fulcrum spoke with the U of O PhD student Tonita to discuss her research published in Joule, regarding her new measuring method that aids in the prediction performance of bifacial solar panels.

What are bifacial solar panels?

According to Tonita, “bifacial photovoltaics are solar panels that collect light on both the front surface and on the rear surface. [Rear side irradiance] is achieved by removing the back plating that holds up the conducting material on a traditional panel, and instead wedging the panel between two pieces of glass. That way you can absorb light coming from both the front and the back (bouncing off the ground).”

Interestingly, she boasted the additional rear side irradiance collected will increase the power (output by the solar panel) by five to thirty per cent in some cases.

Conventional versus bifacial

She explained conventional panels (commonly referred to as monofacial panels) have historically been deployed for the last 30 years. However, recently there has been more and more interest in bifacial technologies due to their performance gains compared to monofacial

technologies. As a result, there has been a greater need for research because of the added complications in trying to predict how the panels will perform in a variety of environmental conditions and locations.

For instance, individuals interested in placing these bifacial panels on a rooftop would be tempted to place them down flat parallel to the surface of the roof, as is conventionally done with monofacial panels. However, this would block that rear side that can serve as an additional light collection site. Thus, bifacial panels are far better off set at an angle, provided the rooftop is not too steep.

Canada is a particularly attractive site for bifacial panels, “because much of the year there’s snow, and as I’m sure we’ve all experienced here in Ottawa walking outside on a sunny winter day, wishing we had sunglasses because the reflection off the snow is [so incredibly] bright we almost need sunglasses,” she added.

Snow reflection is really beneficial for these panels as explained by Tonita due to the high albedo effect or the ability of a surface to reflect light because it can be collected by the rear side of bifacial panels. In addition, she explained that contrary to what many have come to expect, colder temperatures actually improve the efficiency of solar panels.

Measuring solar panels

When asked what it means to measure the output on a solar panel Tonita responded, “we often measure the efficiency, which is how well the panel is able to collect incident sunlight, or the power output of the panel. These two terms are highly correlated values with each other. Power is the output of the panel that can be used for example to charge an electric vehicle or power a building. The efficiency is the power output from the panel in relation to how much sunlight power is hitting the panel.” Silicon panels commonly deployed today have efficiencies around 20-25 per cent, meaning 20-25 pe cent of the sunlight that hits the panel becomes usable electricity.

In terms of measuring efficiency or power, it’s a matter of obtaining your power by contacting both your n-doped and p-doped material and then extracting the current. In order to measure efficiency, you must also understand what your illumination conditions were.

Currently, there are two methods used today to measure bifacial panels, which have been standardized for international use by photovoltaic researchers. “One way of measuring the panel is by illuminating the rear and front of the panel at the same time. The standardized way of measuring a bifacial panel is to illuminate the front side of your module with 1000 W/m2 and your rear side with 200 W/m2”

“However, since illumination must come from the front and the rear at the same time there can’t be anything touching the panel. Thus, it needs to be suspended in free space or the panel must be propped up and mirrors and optics need to be used to direct the light to both front and rear sides,” Tonita explained.

“This can be complicated.” She continued, “the second standardized method involves illuminating the front side of your panel by a higher value that mimics as if it had the 200 W/m2 on the rear side. In a perfectly bifacial device, a front illumination of 1200 W/m2 would perform like a panel with 1000 W/m2 on the front and 200 W/m2 on the rear, but the reality is it’s never exactly perfect. Most panels are optimized to have higher efficiency when light comes from the front than from the rear. A typical bifacial device would need to be illuminated on the front-side with around 1150 W/m2 to mimic performance with 200 W/m2 on the rear.”

To date, the second method is more commonly used since it’s easier to implement. Nevertheless, both methods share the same problem by assuming that the panel is illuminated with 200 watts per meter squared as your rear side light.

This value varies significantly depending on the sun position, weather conditions (sun or clouds), location (or latitude), ground cover conditions (grass or snow), and whether or not the panels move in a direction that tracks the sun’s movement across the sky.

A big question researchers often face is if the measurements taken in the lab actually equate to roughly the power received in the field? As Tonita said, the answer to that is “not exactly”, because that 200 watts per metre squared varies a lot.

A new method

The method Tonita has come up with is one where she’s, “calibrated what the rear side of irradiance should be depending on your ground condition and on whether your system is fixed (not moving) or tracking the sun. So I’ve just reduced the sample space, there’s a number of factors that influence the rear side light, but the ground cover and whether the panel tracks the sun are among most important ones.”

For example, if one were to set up a panel in Ottawa that’s fixed and tilted but not moving with dry grass underneath the panel during the summer, Tonita’s method describes what indoor lab measurements represent that outdoor condition.

She added, “the main goal of this method is trying to reduce the gap between indoor measurements and outdoor performance. Whether it gets integrated into the new international measurement standards or not, its can still be used by scientists to supplement the measurement that are requested or required by photovoltaic researchers.”

Reducing the error by a significant amount depends on both the ground conditions and the location, “for Boulder, Colorado, you can reduce the error of your predicted power output of your panel from up to about 10 per cent by using the scaled rear irradiance method I’ve proposed in comparison with the current standard test conditions.”

For more information on SUNLAB and their continued research in photovoltaic technologies and systems visit their website. For more on Tonita’s specific work visit her google scholar profile.